Article and pictures by Wade (91XCAB) [Edited by Me]

Originally posted on the RPS 3.0L boards as " My T-5 Project"

DISCLAIMER:

This project is not for the meek of mind or pocketbook. It requires extensive machine work and fabrication.

1 - 85-87 Aerostar 3.0 to Toyo-Koygo 5spd bellhousing - $50

1 - 5.0 or 3.8 v6 to T5 bellhousing (borrow one if possible, you will be able to return it in one piece)

1 - Borg Warner T5 prices vary

1 - 85-87 Mustang SVO clutch kit $170.67 list (Valeo #07-501FW pressure plate, disc, throwout, pilot bearing)

1 - Total Performance External Hydraulic Slave kit - $180 (ph586-468-3673)

1 - Mustang V8 shift fork - $59.75 list

1 - Mustang V8 forkball - $33 list)

1 - Mustang bell boot - $13.75 list)

1 - # 2-3-8251X Spicer front yoke - $45

1 - Mustang transmission mount -$10 (Hires#ach2530)

1 - Mustang lower shift boot - $19.95 (dealer will tell you it is not available-Call Late Model Restoration Supply)

4 - 3/8x1.25 flat head socket cap screws

4 - 3/8 locknuts

4 - M12x35mm grade 10.9 bolts (or 1/2x1.5 whichever you want to tap into the bellhousing to attach the tranny)

2 - M12x35mm grade 10.9 bolts (tranny mount to tranny)

4 - M12 flange nuts (two for tranny mount, two for cross member)

2 - M12x25mm bolts (extension flange to cross member)

½ thick 6061-t65 aluminum plate (app. 12"x12)

Ό aluminum (app. 8"x6)

Ό steel (2 pcs app. 4"x4)

3/16 steel (2 pcs 1"x6)

I chose to use a V8 T5 for several reasons.

1. Torque rating: 290 vs. 230

2. First gear ratio: 3.35 vs. 3.97, could you imagine 3.97 first gear with 3.73 rear gears and 26 tires?!?!

3. Overdrive ratio: .68 vs. .79. The only drawback to this is that it does not tow well in 5th at 55-60 mph (17-1900rpm). But it will cruise on the interstate at 2200 at 70mph with no load!!

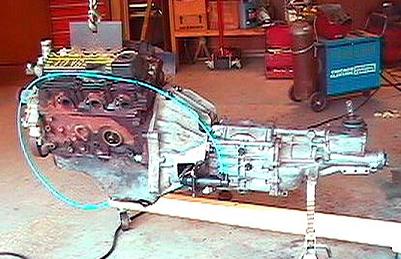

You will need to take the input shaft out of the tranny and have it turned down to the v6 pilot-bearing diameter. Make sure you find a shop that can turn it down, weld it back up and grind it down to the final dimension so that it will be hardened, unless you know someone in the heat treat business who can do it for you. If you only have it turned down, it will be soft as it is only case hardened. I had this performed for around $60.

On to the challenging stuff

The bellhousing is the tricky part. You will probably need to take both bellhousings to the machine/fab shop. They should be able to use the V8 bellhousing as a pattern to layout the adapter plate to bolt to the 3.0 bellhousing. I used 6061-t65 aluminum plate. You may be able to buy it cheap as most of the pieces are of scrap size. We welded ½x1 square blocks to the back of the adapter in the location of the bolt holes, as ½ is not thick enough for m12 bolts (or if you so choose ½ bolts, just be sure to tap the hole for the pivot ball ½x13). Mill .460 off the back of the 3.0 bellhousing (this will leave the ½ adapter plate approximately .040 high). Pin the adapter to the bellhousing. Take careful note of the location of the holes in the v8 bell, if you dont get the holes right, the tranny will be rotated slightly when installed. Flip the 3.0 bell over and drill from the inside through the original mounting holes with a 3/8 bit. Flip the bell back over and using a countersink, countersink the holes in the adapter to a point where the head of the bolt will be at least .045 below the top of the adapter. Drop in the bolts and using the lock nuts, tighten down the adapter to the bell. After all bolts are drawn, mill the adapter to a uniform surface even with the back of the 3.0 bell. This operation alone cost me $300.

|

|

|

Take the Ό aluminum and bend it to match the contour of the v8 bellhousing where the shift fork comes out of the bellhousing, cut the hole to match the opening in the v8 bellhousing. This piece can be welded to the adapter plate. You will have to cut out the side of the 3.0 bellhousing to allow the shift fork to stick through. You will need to use a die grinder, as the bellhousing is magnesium and does not cut well with standard cutting tools [Warning! Magnesium dust is HIGHLY flamable and difficult to extinuish!]. I used a medium body two part epoxy to fill in the gaps around the seams and edges of the plate and bellhousing. It will be impossible to get it water tight, but I figured at least I could try and keep some of the trash from splashing in.

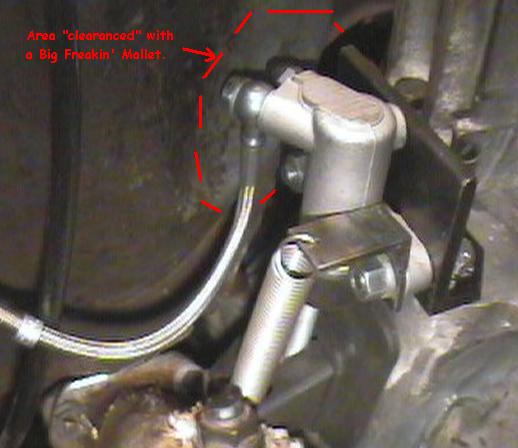

The Total Performance slave is, in my opinion, overpriced for what you get. It uses just a piece of 3/8 all thread rod as the clutch fork actuator. Nice thing about it though is that it comes with a braided stainless line to hook up to the master cylinder. Compared to spending $400 for a McLeod internal hydraulic release bearing, I will pay my $180 and keep my bitching to a minimum. It is intended to be bolted to the back of the bellhousing via bolts THROUGH the back and nuts on the inside. By the time I got mine, I already had the tranny installed, so I ended up having to drill and tap the back of the bellhousing, Major PITA. Just follow the directions that come with the kit, and you should be just fine. One last thing, I have NEVER been a sledgehammer mechanic, but no matter what I did, I could not get the slave to clear the corner of the floor pan under the truck, and ended up having to take a hammer and make clearance for the slave cylinder.

At this point you should be able to fit the tranny and bell up into truck. The T5 was exactly 2 shorter than my A4LD. I dont have any idea what the length difference would be for a M5OD. You will need to use a new yoke, as the T5 shaft is larger. I took my drive shaft in and had the front tube removed and a longer tube put in. You standard cab guys may elect to use a longer splined yoke since you have a one-piece shaft, and they charge by the INCH ($.66 per INCH! Plus labor) to retube a driveshaft.

Rather than move the cross member forward to line up with the mount, I fabricated an extension bracket for the mount to sit in. Definitely use the Mustang tranny mount. The Ranger mount will bolt up to the T5, but the Mustang mount has twice the rubber bonding area, weighs half as much and cost a third of the price! I used two pieces of Ό steel plate and overlapped them about 1.25. If you put the back piece on the top, the tranny mount will sit at the same height as the cross member. I used the 3/16 steel to weld gussets on the sides to give it more strength. Drill your holes to line up with holes in the cross member and in the tranny mount (make sure you measure the center to center difference in the holes before drilling). I welded in the M12 bolts at the back so that I could just put nuts on the bottom of the cross member and not have to double-wrench.

You will have to cut a new hole in the floor for the shifter. The center of the shifter will hit right on the back of the factory hole. Since I had an auto, I just needed to cut the hole where I needed it. If you have a stick, you may want to scour the yards for an automatic truck and get the floor plate from it to seal off the front of the factory hole. I took a piece of naugahyde (fake leather) and just cut and sewed my own floor boot. I ordered a Mustang floor gasket from Late Model Restoration Supply and used it as a pattern for the boot and the trim ring. For the shifter rod, I just used a piece of Ύ mild steel bar stock and cut the bottom down the center to make a half moon and bolted it on the shifter. I welded an M12 bolt on top and ordered a Billet Mustang Shifter Handle from MAC performance.

|

|

Enjoy!